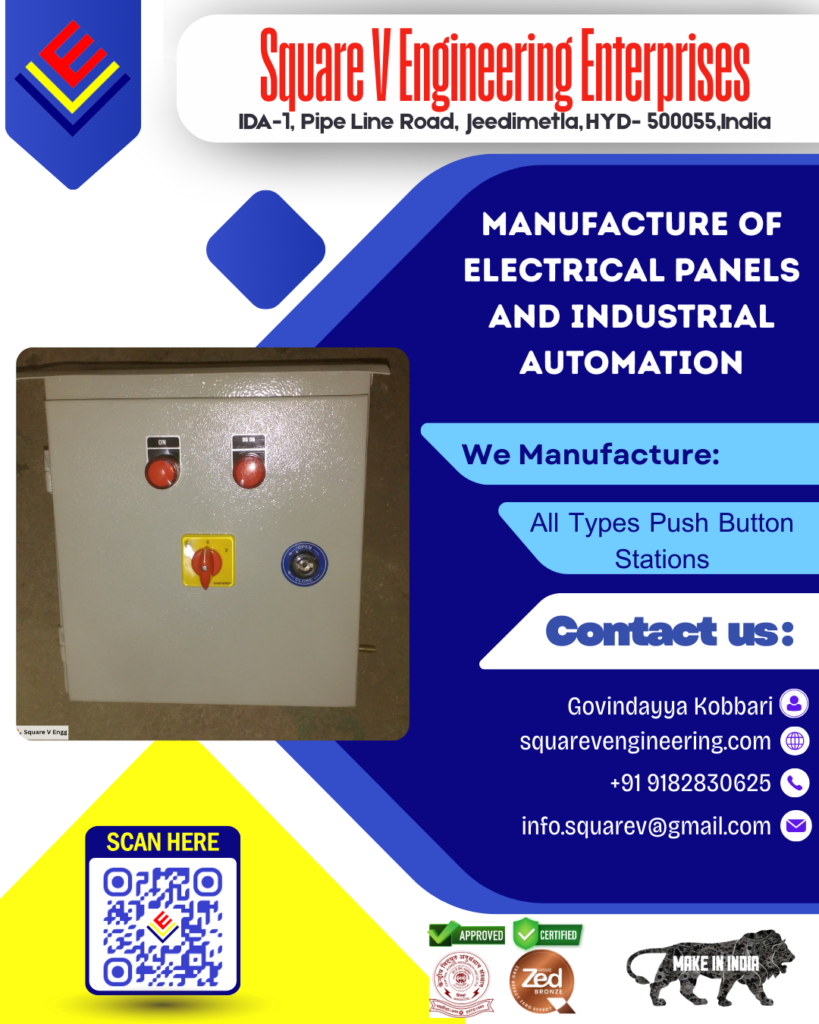

Push Button Stations

Understanding Local Push Button Stations in Electrical Panels

Local push button stations are operator interfaces that allow direct control of motors and equipment. They are widely used in industrial plants, workshops, and outdoor installations where quick access and safety are critical.

🔌 Types of Local Push Button Stations

1. DOL (Direct-On-Line) Starter Stations

- Purpose: Start and stop motors directly by applying full line voltage.

- Applications: Small to medium motors (up to ~10 HP) in pumps, fans, and compressors.

- Simple design with Start (Green) and Stop (Red) push buttons.

- Overload protection integrated.

- Best suited for indoor installations where environmental conditions are controlled.

2. RDOL (Reverse Direct-On-Line) Stations

- Purpose: Provide forward and reverse control for motors.

- Applications: Conveyor belts, mixers, and machinery requiring directional control.

- Includes Forward, Reverse, and Stop push buttons.

- Requires mechanical/electrical interlocking to prevent simultaneous operation.

- Can be installed indoor or outdoor with proper IP-rated enclosures.

3. Pendant Control Stations

- Purpose: Portable control for hoists, cranes, and lifts.

- Applications: Material handling in factories, warehouses, and construction sites.

- Suspended from equipment with a flexible cable.

- Multiple buttons: Up, Down, Left, Right, Emergency Stop.

- Designed with dust and rain resistance (IP65/IP66) for rugged outdoor use.

4. Workstation Push Button Panels

- Purpose: Centralized control for multiple machines or processes.

- Applications: Assembly lines, workshops, and testing stations.

- Mounted on desks or panels.

- Can integrate multiple functions: Start/Stop, speed control, emergency shutdown.

- Typically indoor installations, but outdoor versions exist with weatherproof housings.

🌍 Indoor vs Outdoor Considerations

⚠️ Key Safety & Design Tips

- Always use IP-rated enclosures for outdoor stations.

- Ensure emergency stop buttons are accessible and clearly marked.

- For RDOL stations, interlocking is mandatory to avoid motor damage.

- Pendant stations should have ergonomic grips and strain relief to prevent cable wear.

- Regular inspection and cleaning extend life and reliability.

✅ Conclusion

Local push button stations—whether DOL, RDOL, pendant, or workstation panels—are essential for safe and efficient motor control. The choice between indoor and outdoor installations depends on environmental conditions, operator convenience, and safety requirements. By selecting the right type and enclosure, industries can ensure long-lasting, reliable, and safe operation of their electrical panels.